Why Argon Gas is Used for Welding

Argon Gas and its Role in Arc Welding

Behind the scenes of welding, an invisible gas plays a crucial role: argon. Unlike the high-powered equipment that generates intense heat, argon's contribution is subtle yet essential. This article explores the nature of argon gas and its vital function in creating strong and reliable welds.

What is Argon Gas?

Argon is a noble gas, the third most abundant element in Earth's atmosphere. It's colorless, odorless, and chemically inert, meaning it doesn't readily react with other elements. This inert property is what makes it invaluable in arc welding processes.

Air Contamination:

During arc welding, intense heat melts the base metal and, if used, filler metal, creating a molten weld pool. However, the surrounding air poses a threat. Oxygen and nitrogen from the air can react with the molten metal, forming oxides and nitrides. These can weaken the weld, making it brittle and prone to cracking.

Argon: The Invisible Shield

Here's where argon gas comes into play. In arc welding processes like MIG (Metal Inert Gas) and TIG (Tungsten Inert Gas) welding, argon is used as a shielding gas. A steady flow of argon is released from the welding torch, forming a protective bubble around the weld zone. This inert gas displaces the air, preventing oxygen and nitrogen from reaching the molten metal.

The Benefits of Argon Shielding

By shielding the weld pool from air contamination, argon offers several advantages:

- Stronger Welds: Reduced interaction with oxygen and nitrogen prevents the formation of weak spots, leading to stronger and more durable welds.

- Improved Weld Appearance: Argon helps prevent spatter and oxidation on the weld surface, resulting in a cleaner and more aesthetically pleasing weld bead.

- Arc Stability: A stable and consistent arc is crucial for good weld quality. Argon helps maintain arc stability by minimizing disturbances from air currents.

Argon Safety:

While argon gas is inert and poses minimal health risks during normal welding use, some safety precautions are still important. Argon can displace oxygen, so ensure proper ventilation in enclosed spaces to prevent oxygen deficiency. Inhaling large amounts of argon can lead to dizziness or suffocation. When handling argon cylinders, always wear safety glasses and gloves, and secure them upright to prevent tipping.

Argon in Welding:

- Gas Tungsten Arc Welding (TIG): Pure argon is the standard shielding gas for TIG welding on various metals, including aluminum, magnesium, and stainless steel.

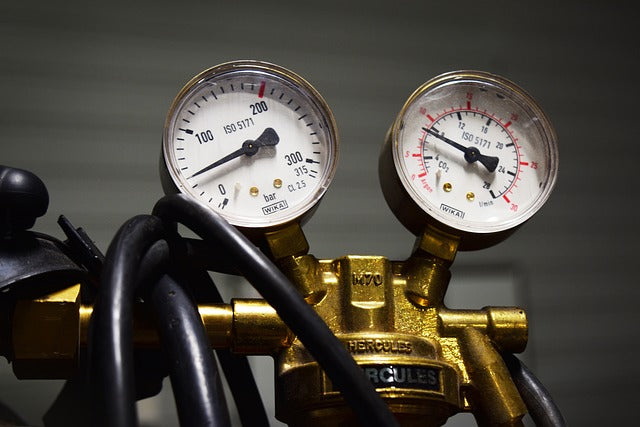

- Metal Inert Gas Welding (MIG): While pure argon can be used for MIG welding on some thin metals, a mixture of argon and carbon dioxide (CO2) is often preferred. The CO2 adds penetration characteristics to the weld.

Conclusion:

Though unseen, argon gas plays a critical role in the success of arc welding. By shielding the molten metal from air contamination, it ensures the creation of strong, reliable, and aesthetically pleasing welds.

1 comment

Dear manager, our factory is specialized in producing calcium chloride, magnesium chloride, sodium bicarbonate, sodium metabisulfite, caustic soda, calcium carbide ,PAC, sodium bromide and calcium bromide,if needed in later time, pls feel free to contact us, thanks